Producing Hand-Sewn Chapbooks With Block Print Covers

Tools, Tips, and Techniques

Use Bearer Bars for Consistent Inking of Relief Blocks

Applies to many hand-print methods that are alternative to using a commercially made letterpress.

The ink rollers on platen presses ride on bearer bars to ensure delivery of a thin uniform film of ink to the block being printed. It is difficult to deliver a thin uniform film by hand rolling, difficult to the point of impossibility.

Part of the difficulty in delivering a thin film is the tendency of the roller to cause a slur if thicker ink at the point the not--yet-moving roller hits the block, often with the initial impact being somewhat to the side of the block rather than on the printing surface of the block.

The solution to better delivery of the ink film to the block is to use rollers of larger diameter and wide enough to ride on “ink-bearers” which are bearing surfaces that are on either side of the block intended to limit lower travel of the rollers.

Normally, on platen presses the ink bearers support the rollers type high so the rollers make light contact with the block. If you are using a platen press the bearers are already present and the only concern given the rollers is to keep them clean and in some cases add a layer of tape the bearing surface if it is worn and and has lost height.

Rolling ink using ink-bearers introduces a messy problem that has a convenient cure. The problem is that the ink-bearers become covered in ink which in turn would lay a ribbon of ink onto the printed page. The solution is to use a Frisket as described in other sections of this page.

Using bearer bars gives an advantage when making the impression. Prints are made more uniform by using the bearer bars to support the roller or platen used for printing. Like traditional platen press printing, variations in impression are better controlled in makeready or in adjustment to packing between the roller/platen and the paper being printed.

See our sections on Friskets and Inexpensive Type-High Roller-Bearing Chases for details on an effective approach that is simple and inexpensive.

(*Note:Acrylic prep is a light paint coat only for improved carving visibility and pattern transfer. Wipe light film onto block using soft cloth. Yellow acrylic gives better visibility than white and is easier on the eyes.)

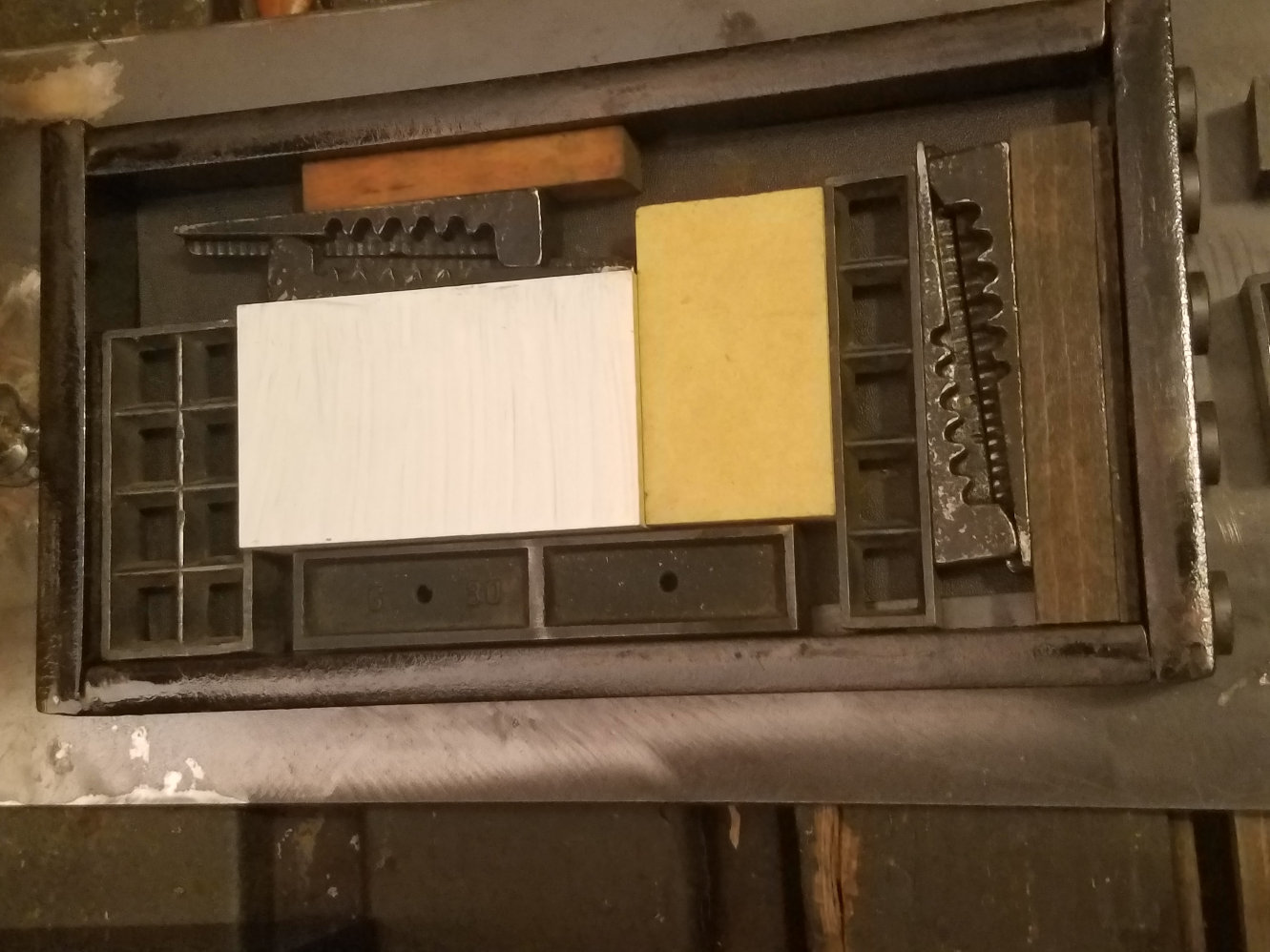

Entire Woodcut and Chapbook Binding Shop in a toolbox

Three-drawer tool box contains everything needed to carve woodcut and all bookbinding tools to produce sewn chapbooklet

This toolkit allows me to produce woodcuts and chapbooks on the road or in workshops and conveniently lets me find everything in one place when at home.

A kit-in-a-toolbox provides sustainable, repeatable, and portable facility for producing chapbooklets and their covers anywhere. Includes:

- Triple-purpose Woodcarver's Bench Hook: 1) serves to safely secure wood block for carving, 2) as precision folding jig for book block and covers, and 3) as part of the book plough for trimming book pages.

- Acrylic Plates: used in book plough to precisely cut book page widths for smooth book fore edge.

- Acrylic-plate Finders: Clear acrylic with print target marked in sharpie. Used for locating best location of print on book cover. Used also to locate the block in the lockup and to adjust page gauge pins on the Frisket. The gauge pins determine where the sheet to be printed sits in relationship to the block.

- Gouges: U and V gouges for carving woodblocks, also a graver and some X-acto and razor blades.

- Sharpening compound: large tube of red rouge polishing compound, couple sticks of compounds made with chromium and aluminum oxides. Used for sharpening gouges and X-acto blades

- Piece of thick leather for use as sharpening strops. Also piece of wood with V-shaped groove worn in for sharpening V-gouges. See section on Sharpening Gouges for details.

- Punching Cradle: Beautiful maple tool for accurately punching holes for sewing into the signatures of the book block .

- Sewing needles and polished Irish Linen bookbinding thread

- Piercing Awls for punching holes in pages to be sewn into signatures. One effective awl formed by mounting heavy sewing needle in a wine-bottle cork.

- White PVA glue. My bottle of glue is years old. I only use around four drops of glue per book.

- Bone Folders: We have never found anything that works as well as polished bone.

- Steel Roller: 1.5 inch diameter twelve inch length. Only carry it in box if planning to use a roller rather than a platten for impression. (Prefer our DIY platen press so the roller is rarely used, usually removed from box and left at home)

- Sketch pad

- Pencils, Sharpie pen, sharpeners for pencil, pieces of chalk. Pencils are of various hardness, soft for drawing transfer.

- Cherry panels for carving as woodcuts. Assorted sizes mostly 2.5” X 3”. Most prepared for carving with a light coat of yellow paint for better visibility.

- Small flashlight.

- Wifi Hotspot and portable credit card machine Magnifying glass

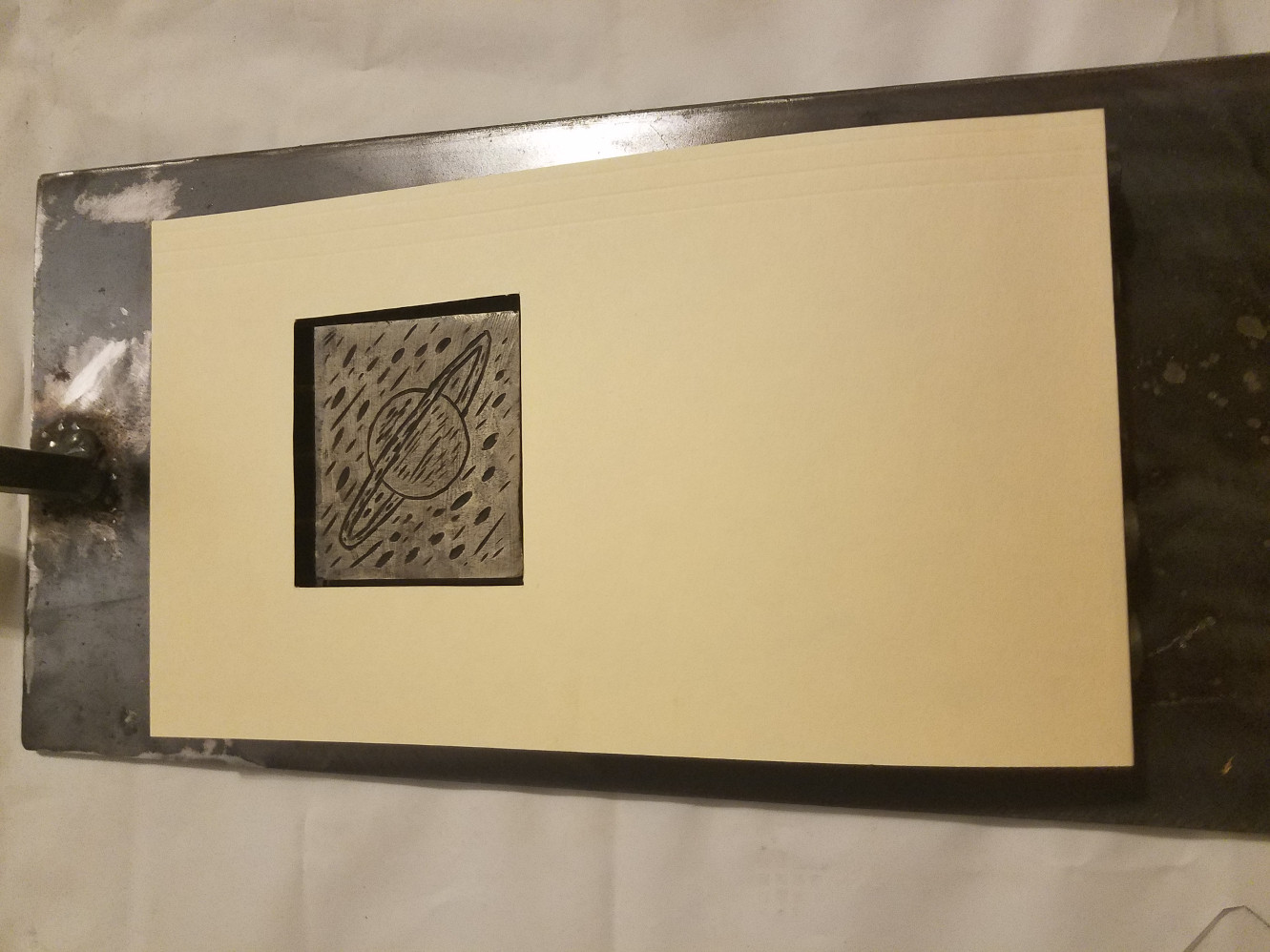

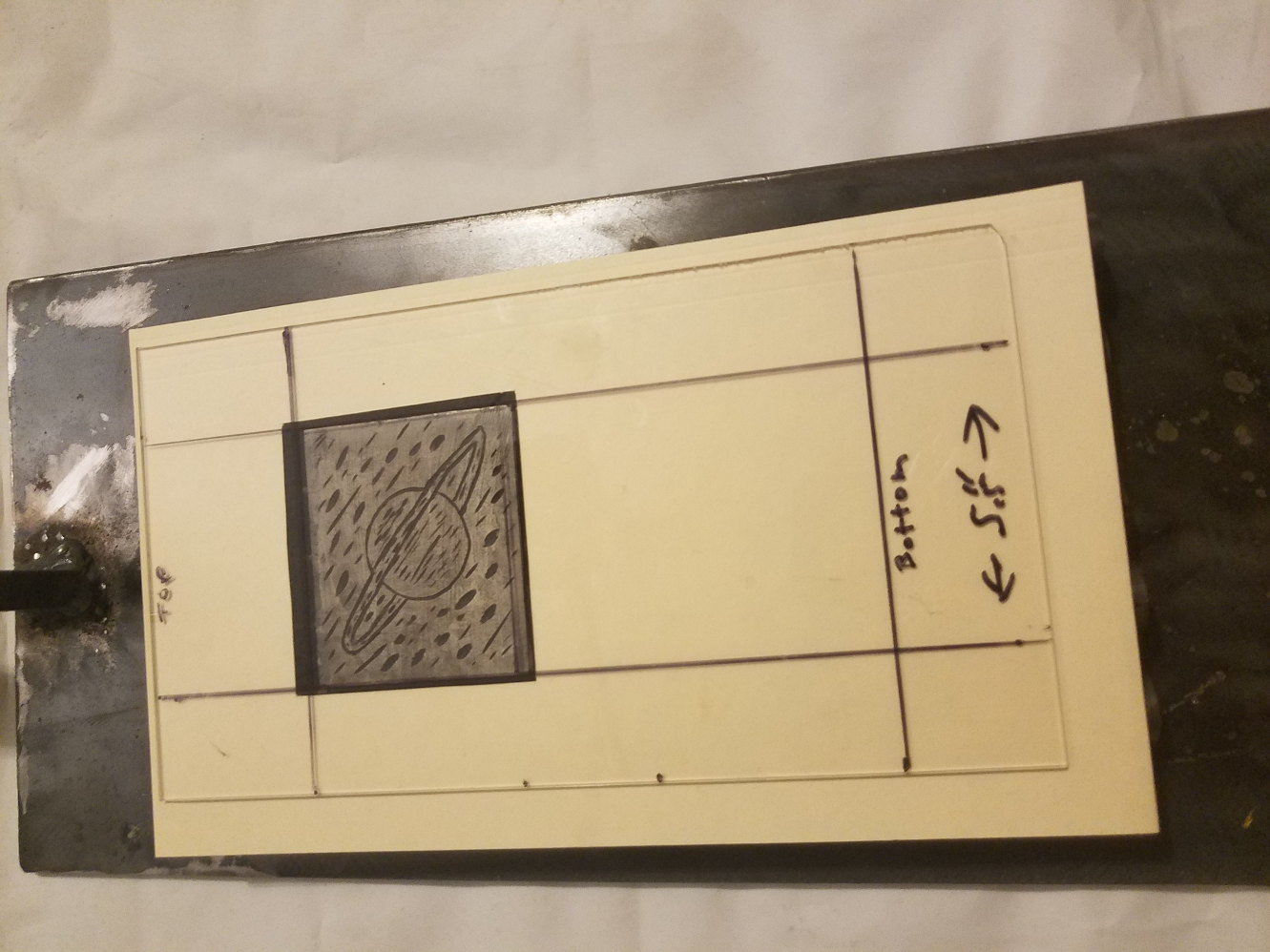

A Sensible Frisket for Horizontal Printing: Construction and Use

The frisket used on a horizontal relief press or letterpress shields the print from ink on the ink-roller bearers and other soiled surfaces while also eliminating the need for a tympan.A frisket made from card stock or cut from a Manila folder can be mounted directly to the chase using magnets on the end if provided with a "hinge" created by a crease 1/2" from the bottom edge. The location of the cutout is easily set by lightly inking the printing block and lowering the frisket to make contact. Then simply raise the frisket, flip it over onto a cutting surface and use an X-acto knife to make the cutout. Five half-inch button magnets works well for six-inch wide chase. Rare earth magnets work very well but are a bother because of their strength.

Gauge pins are placed on the top side of the Frisket. Their location can be determined through use of a transparent finder marked with the print target area and page outer dimensions.

Alternatively, to locate the gauge pins, the block can be removed from the lockup and fastened to intended target area of one sheet of your printing paper. The block is then lowered through the frisket into the form. The page edges now serve to indicate the gauge pin locations

For short runs of less than a hundred impressions we tend use bits of paper glued to the frisket as substitute for the gauge pins. Works very well, but over time the bits are damaged on their edges by the repeat contact with the target pages as they are placed into position on the frisket.

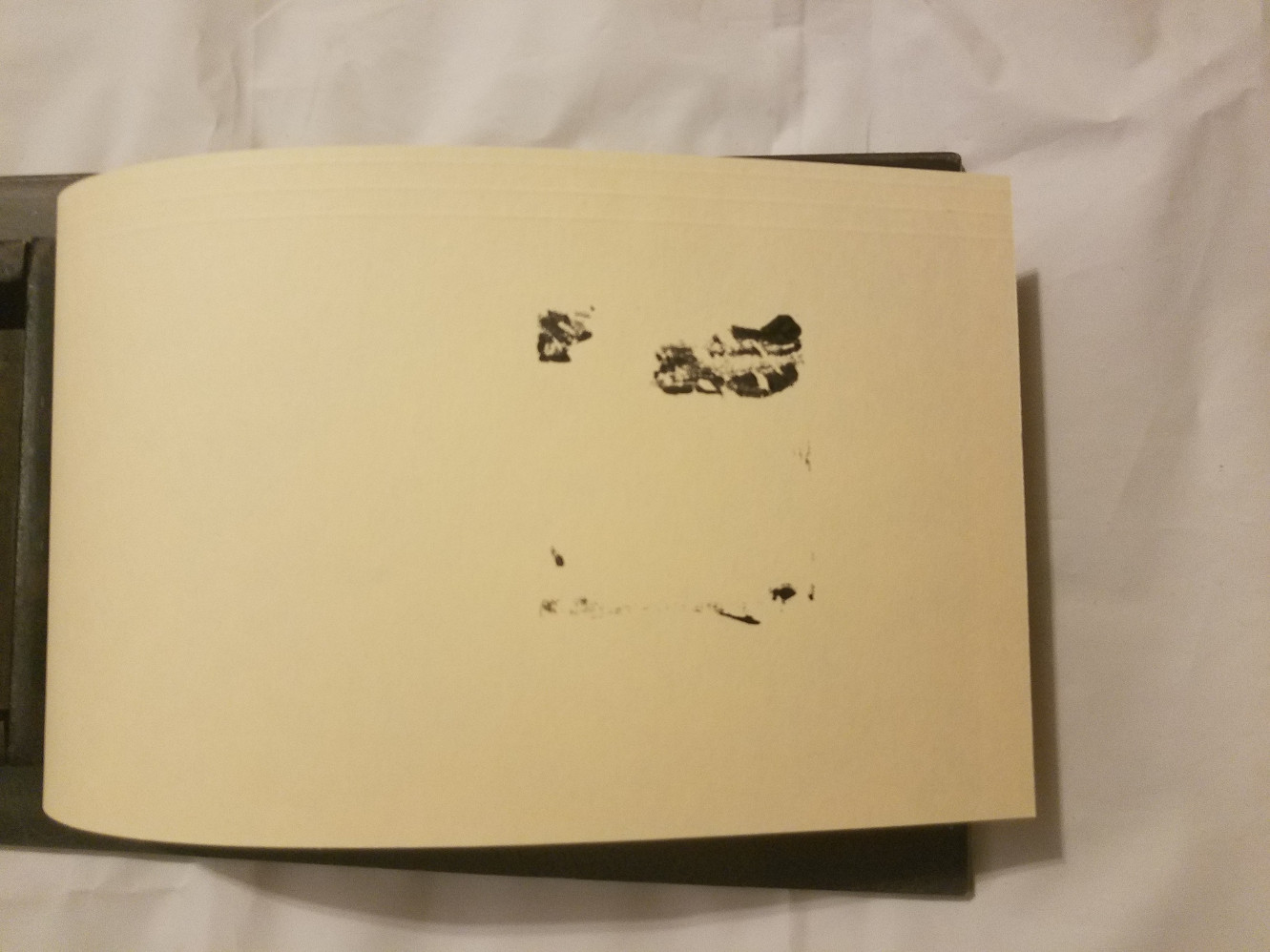

The Photos below show the steps for creating, cutting and then marking the frisket.

Simple Powerful and Portable for Block and letterpress Printing

Craftsman Letterpress, Vandercook SP-1 Proof Press, Antique Book Press, and the Simple Portable Press

Chapbooklets,com presses include the Craftsman tabletop letterpress shown, a Vandercook SP-1 bed press, an antique bookbinder's press, and a simple portable press, an etching press. We recently sold our large Chandler and Price Old Style.

The Craftsman is great for producing consistent prints for longer print runs and the Vandercook is one of the most versatile presses we have ever used.

Book presses are used for bookbinding and they are really not very useful for relief printing, in spite of what many web pages say.

For the last couple of years we have used the simple portable press more often than the others because it produces good results and is ... simple.